Minimizing Fouling, Protecting Equipment

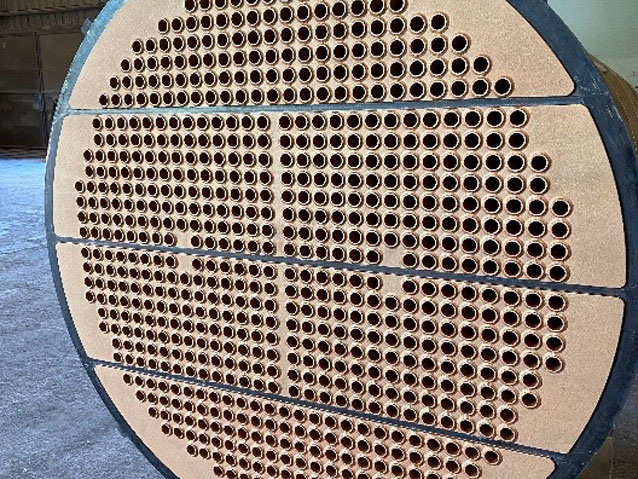

Curran International is recognized globally for its long-lasting, cost-efficient exchanger tube ID coatings. These coatings help refineries minimize fouling and inhibit corrosion, protecting both the thermal performance and mechanical integrity of heat exchangers. Fouling reduces heat transfer, creating production bottlenecks and increasing maintenance downtime, while corrosion threatens equipment safety and reliability. Curran coatings provide a proven solution to both challenges.

A Wide Selection of Proven Coatings

Refinery engineers can choose from a full portfolio of Curran Thin Film Coatings, designed to reduce surface energy and enhance release at the substrate. By combining advanced materials with expert application techniques, Curran delivers anti-fouling solutions that improve efficiency and reduce routine maintenance.

Curran’s coating materials include:

- Thin Film and Nano Sol Gel Coatings such as DTI and Curramix 2500, ideal for crude, hydrocarbon, and produced water services. These coatings are functional at less than 25 microns thickness and suitable for temperatures up to 200°C (390°F), making them perfect for plate and frame exchangers or tubular IDs/ODs.

- Epoxy Coatings, including Curran 1000T, StreaMax™, and Teflon™ Ruby Red PFA, for cooling water systems and corrosive services. These coatings offer thicknesses from 100 to 250 microns and protect against galvanic attack and low-pH oxidizing environments, with service temperatures up to 200°C.

- Ceramic Coatings, such as Nano-REE and Curramix 3500, engineered for coke and crude fouling, high-temperature oxidation, and distillation tower structured packing. These coatings are suitable for extreme temperatures up to 1000°C (1830°F) and provide long-term protection for IDs, ODs, and high-temperature applications.

Proven Global Performance

Many international refineries have relied on Curran-coated exchangers for more than a decade. For example, in a large Fluid Catalytic Cracker (FCC) unit, Curran-coated cooling water exchangers in the Main Column Overhead Trim and HP Receiver Overhead Trim sustained duty even when fouled condensers would otherwise reduce reactor performance.

Operational Benefits Observed:

- Improved Reactor Yield: Fouled condensers struggle to condense properly, increasing reactor back pressure and reducing efficiency. Curran coatings maintain proper condensation, ensuring optimal reactor operation.

- Enhanced Propylene Recovery: By minimizing fouling, coated exchangers reduce absorber outlet temperature, supporting higher propylene recovery and smoother plant operations.

Curran coatings are proven across a wide range of services, from cooling water and crude processing to hydrocarbon and high-temperature coking, delivering reliable, long-lasting performance that reduces maintenance and improves operational efficiency.

Mitigating Fouling for Better Compressor and Steam Performance

Fouled condensers can reduce heat transfer efficiency, contributing to higher vapor flows to wet gas compressors (WGC), which increases compressor brake horsepower (BHP) and HP steam consumption. Curran International’s tube-ID anti-foul coatings help mitigate fouling and restore optimal tube-side cooling water flow. This improvement increases the Log Mean Temperature Difference (LMTD), enhancing overall unit performance and generating measurable operating cost savings.

Proven Results in FCC Feed Preheat Exchangers

At a large Gulf Coast refinery, Curran applied a thin film ID coating to the tubes of a Fluid Catalytic Cracker (FCC) Bottoms/Feed Exchanger. Initially, heat transfer efficiency (Uclean) dropped slightly by 5% after application. However, after five months of operation, the refinery reported a 20% improvement in overall heat transfer rate (Uservice). More than two years later, the exchanger continues to operate with better feed preheat temperature and slight improvement in unit performance, demonstrating the long-term value of Curran coatings.

A Cost-Effective Solution

While the impact on unit throughput and crude production may not always be immediately visible, the operational benefits of coated versus uncoated exchangers can be substantial. Curran’s anti-fouling and corrosion-resistant coatings deliver reliable, long-lasting performance, helping refineries maintain efficiency and reduce maintenance downtime.

Learn More

To explore anti-fouling and corrosion-resistant exchanger coating solutions, contact Alex Barre at abarre@curranintl.com or call 281.339.9993. More information is available at www.curranintl.com.