Curran International is a trusted provider of advanced solutions for heat exchangers and their components, designed to reduce fouling, increase corrosion resistance, and extend equipment life.

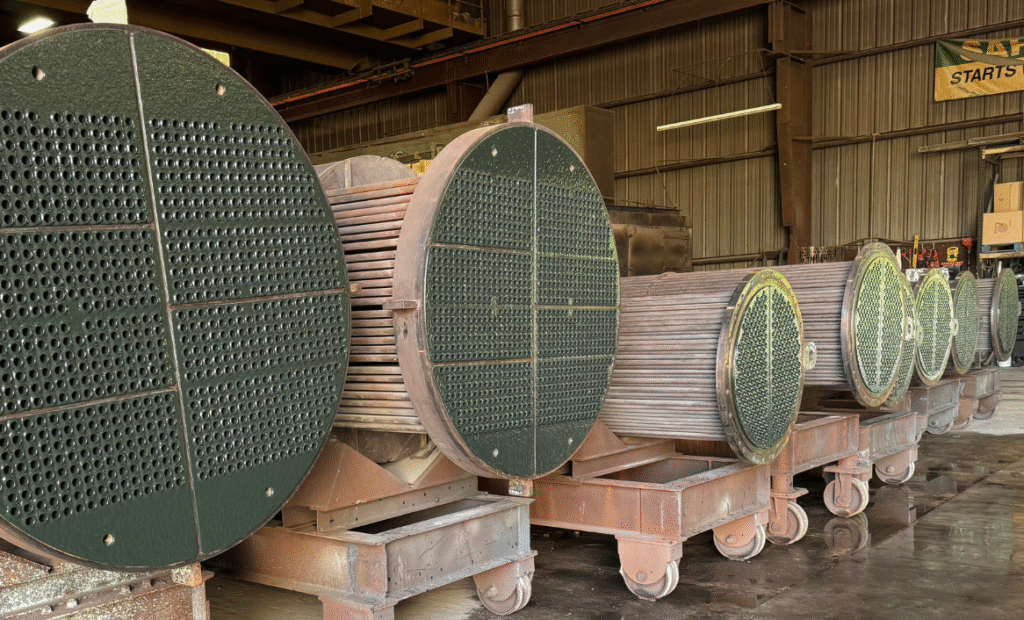

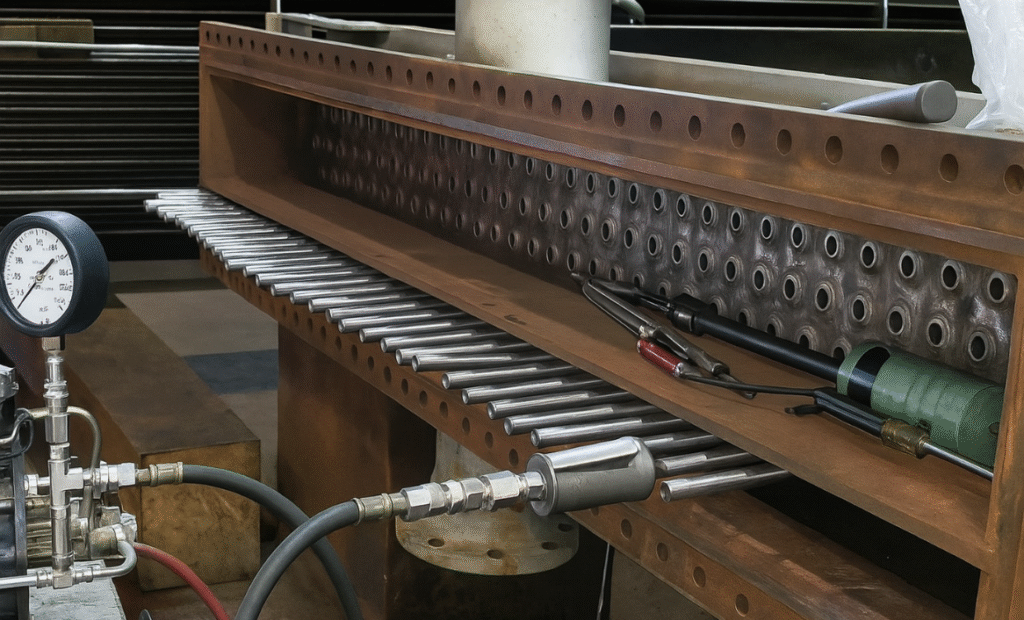

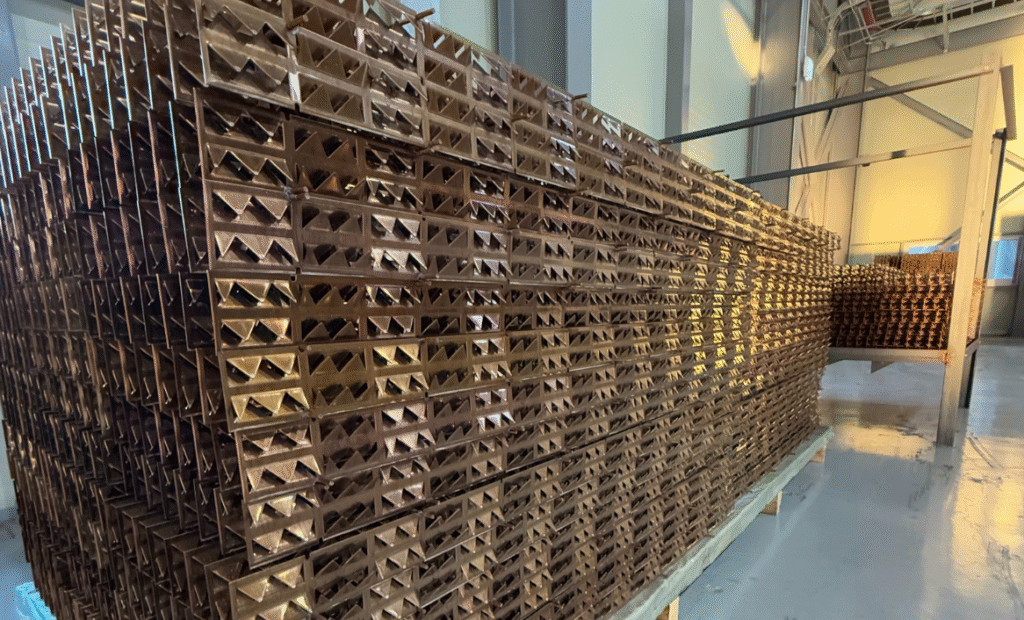

We apply anti-fouling and corrosion-resistant coatings to both the tube side and shell side of exchangers, enhancing thermal efficiency and minimizing unplanned outages. Our services also include full-length alloy tube liner procurement and installation, as well as proprietary tubular grit blasting to prepare surfaces for inspection and coating.

From crude preheat trains and cooling water exchangers to fin fans, distillation towers, condensers, and boilers, Curran helps clients across industries improve reliability, lower energy consumption, and defer costly capital replacements.

Delivering Solutions without Boundaries

We begin by working with your team to understand the current state of your heat transfer equipment. Identifying fouling, corrosion, or performance issues that may be impacting efficiency or reliability.

Our team evaluates the data and operating conditions to determine which Curran solutions will provide the most impact. Whether that's coating technology, alloy liners, grit blasting, or a combination.

We develop a tailored solution that may include our advanced coatings, tube liners, or grit blast cleaning services, designed to meet your unique equipment needs.

Our skilled technicians provide professional installation or application of our solutions, either in situ at your facility or at one of our facilities worldwide, ensuring optimal performance and long-term reliability of your heat transfer equipment.