Cut fouling. Boost efficiency. Reduce CO₂.

Heat exchanger fouling is one of the most expensive challenges in refinery and petrochemical operations. The consequences are wide-ranging:

- Lost production capacity

- Higher maintenance costs

- Poor asset utilization

- Increased CO₂ emissions

Globally, fouling is estimated to cost 0.25% of GDP—in the United States alone, that’s about $537 billion per year.

In refining, operational fouling contributes an estimated 88 million tons of CO₂ annually.

For a single large manufacturing facility, the impact can reach hundreds of millions of dollars each year.

A Brief History of Coatings

For decades, high-performance epoxy coatings have been applied to heat exchangers—primarily for corrosion protection.

- Typical thickness: 200–300 microns

- Benefits: corrosion resistance, reduced or eliminated fouling, improved throughput, fewer cleaning outages

- ROI: measurable and verifiable

However, the relatively thick film builds sometimes raised concerns about potential heat-transfer penalties, slowing widespread adoption—especially in units with tight thermal margins.

New Materials. New Solutions.

In the last decade, materials research has transformed the coating landscape.

Today’s durable thin-film coatings:

- Operate from -40°C to over 1000°C

- Deliver low-surface-energy finishes that repel fouling

- Offer multiple mechanisms for fouling prevention:

- Dielectric barriers to block ionic exchange

- Low-energy materials (e.g., silicone, fluoropolymers)

- Low polar value, ultra-smooth surfaces

These coatings range from sub-micron (nano) thickness to 50 microns—thinner than even a light fouling layer. Thermal modeling shows fouling factors well below design allowances, meaning no significant penalty to heat transfer.

Application Versatility

Modern coatings can be applied to a wide variety of exchanger surfaces:

- Tube inner and outer diameters

- Plate-and-frame

- Spiral

- Finned surfaces

- Twisted Tube®

- Other enhanced geometries

Application techniques have evolved alongside the materials to ensure adhesion and performance across these designs.

Proven Anti-Foul Applications

Several coating systems are now fully developed, tested, and deployed in real-world refinery and petrochemical service. Results include:

- 10× average return on application investment

- Significant reduction in fouling rates

- Lower cleaning frequency and maintenance costs

- Reduced CO₂ emissions through improved thermal efficiency

Epoxies remain a trusted workhorse:

- Carbon steel service: 200 microns (.008”) for corrosion protection

- Less reactive alloys (duplex SS, 304, 316, copper-based): often just 50 microns or less

Proven Coating Technologies

Siliconized & Fluoropolymer-Infused Epoxies

- Well-established for cooling water and process water systems for over 30 years.

- Applied at 50–200 microns, serviceable up to 200°C, with an expected 10–20 year life.

- High-temperature operation (>70°C) can slowly oxidize standard epoxies, increasing surface energy and roughness—creating fouling sites.

- Fluorinated or silicone-modified formulations maintain low surface energy, resist oxidation, and provide a durable antifouling layer.

Sol-Gel Coatings

- Silicone-based thin films, 5–25 microns, with ultra-low surface energy (~20 mN) and low roughness (0.5 micron Ra).

- Elastomeric and abrasion-resistant, suitable for plate-and-frame exchangers, crude, and crude/water solutions.

- Proven to extend cleaning intervals from months to years.

- Functional temperature range: -100°C to 300°C, compatible with all common metallurgy.

Fluoropolymer Coatings

- Initially used for “release” and antifriction; early thin films lacked durability in immersion.

- Modern thin-film fluoropolymers (~75 microns) provide excellent adhesion, corrosion resistance, and low surface-energy release.

- Successfully deployed in high-fouling water/crude services and other corrosive environments.

- Effective up to 250°C (500°F), with excellent performance in caustic, acidic, and process water services.

Ceramic Coatings

- Pre-ceramic polymers offering low surface energy, excellent adhesion, chemical resistance, and high thermal stability.

- Amorphous state stable up to 400°C, sintered crystalline form up to 1000°C.

- Typical application: 10–25 microns, cold- or heat-cured.

- Ideal for furnace and high-temperature fouling applications.

Sintered Ceramics

- Designed for anti-coking services in ethylene steam cracking furnaces.

- High-temperature vacuum-cured; service up to 900°C.

- Demonstrated threefold extension of decoking intervals, improved operational efficiency, reduced CO₂ emissions, and mitigated metal fatigue.

Nano Metal Oxides

- Serve as thermal barrier coatings with low surface-energy properties.

- Applied at sub-micron thickness, stable at temperatures up to 1000°C.

- Used for high-temperature furnaces, towers, and heat exchangers.

Benefits Observed in the Field

Clients deploying advanced coatings have reported:

- Reduced CO₂ emissions

- Maintained exchanger duty

- Improved Log Mean Temperature Difference (LMTD)

- Extended runtimes or elimination of cleaning events

- Enhanced flow rates through exchangers

- Process efficiency improvements with up to 10× return on investment

These coatings allow heat exchangers to perform as designed, maximize throughput, and minimize cleaning downtime.

Curran Expertise

Curran International specializes in advanced coatings for all heat exchanger types and operating conditions. Applications include:

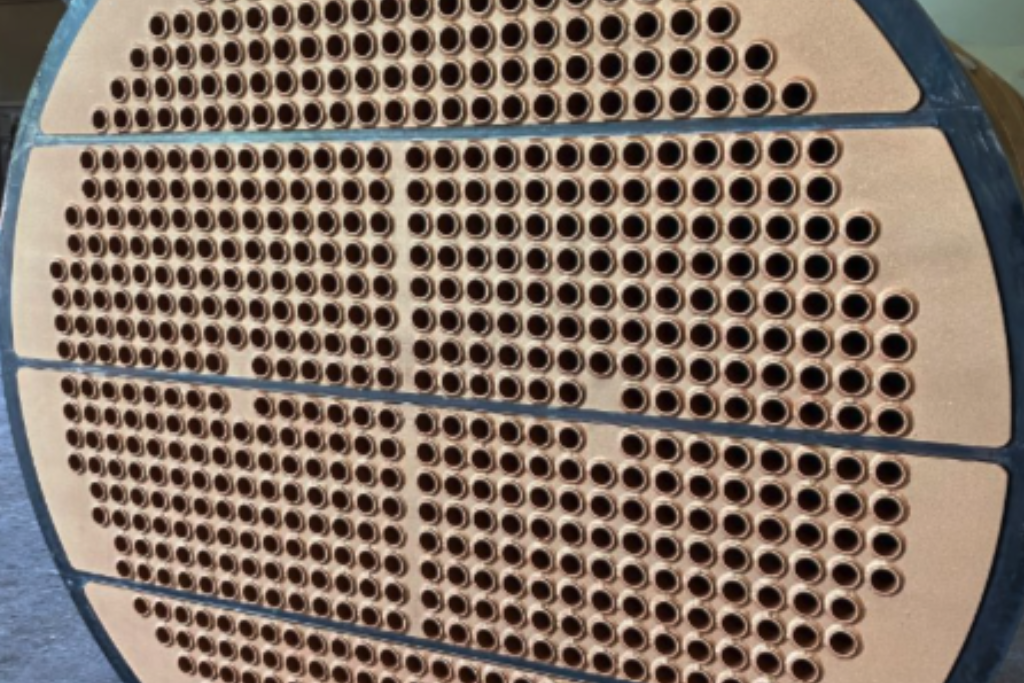

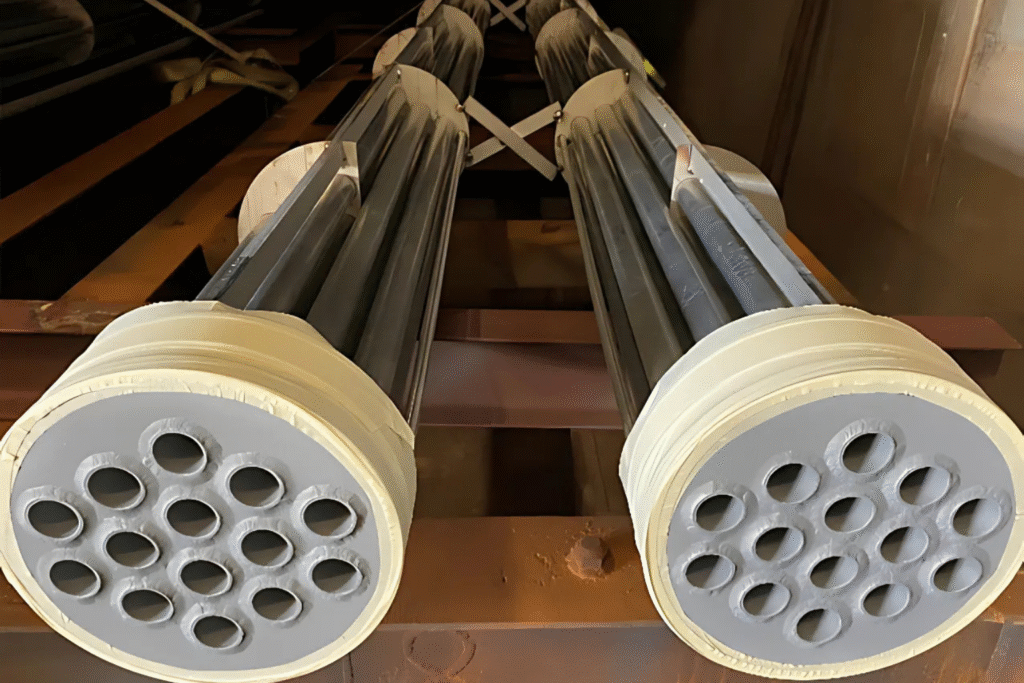

- Hairpin, plate-and-frame, and shell-and-tube exchangers

- Full-length tube ID coatings, including thin ceramic and fluoropolymer films

- Fouling, corrosion, and high-temperature mitigation

Contact Curran International:

🌐 Curran Foul-Release Exchanger Coatings

📧 Edward Curran — ecurran@curranintl.com

Catch Curran Live in San Antonio…

• AMPP 2022 Conference + Expo 2022, Henry B. Gonzalez Convention Center, March 6 – 10.

Curran exhibiting, Booth # 2235

• API 2022 Inspection and Mechanical Integrity Summit, Henry B. Gonzalez Convention Center, August 9 – 11.

Curran’s Booth TBD.