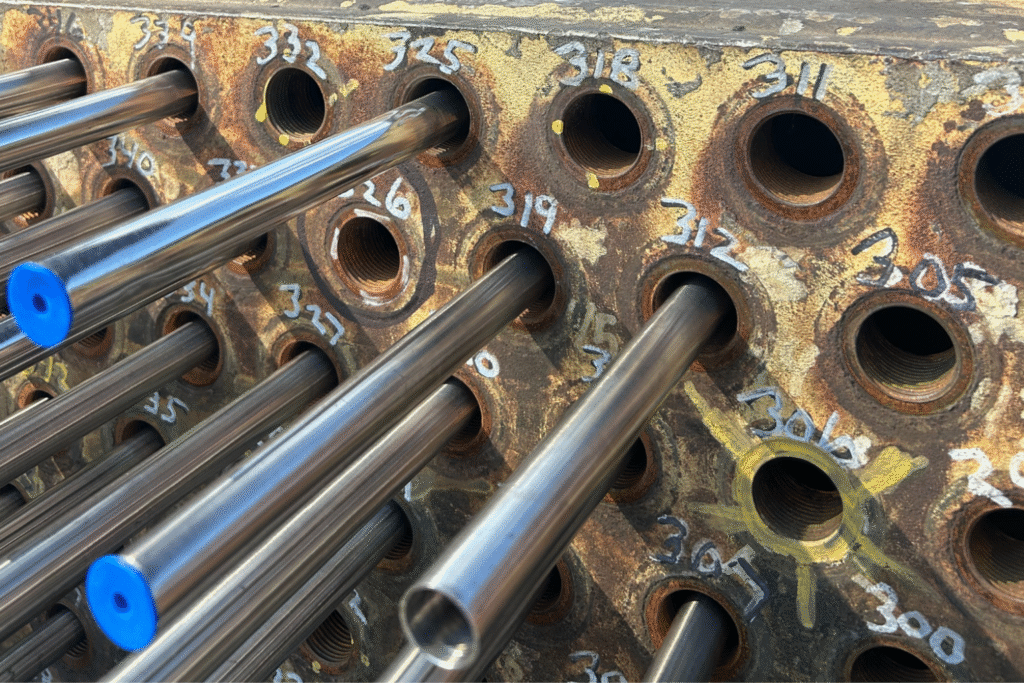

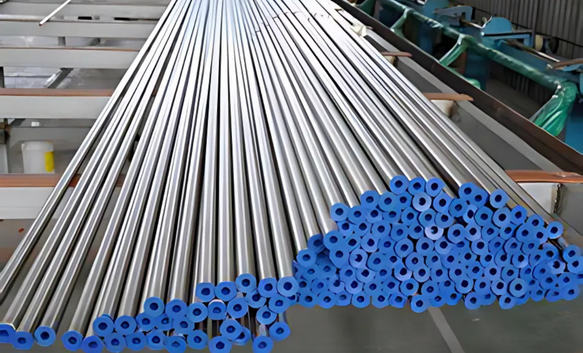

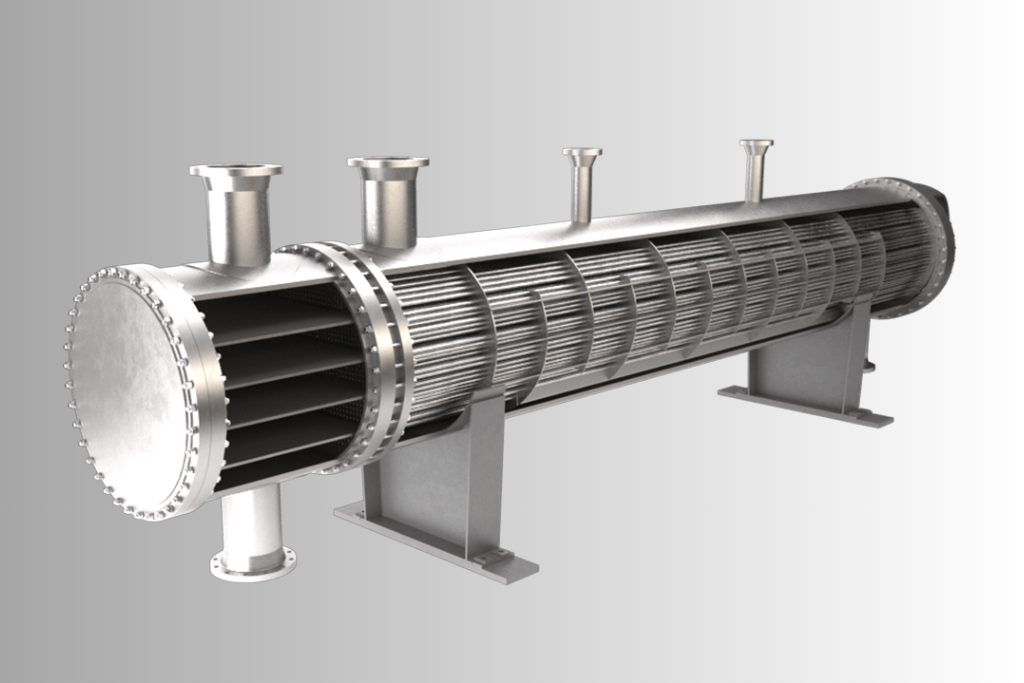

Full-length alloy tubes hydraulically expanded inside existing parent tubes to provide corrosion and erosion protection. Available in stainless steel, duplex, Inconel, CuNi, C276, and other specialized metallurgies for upgrade applications.

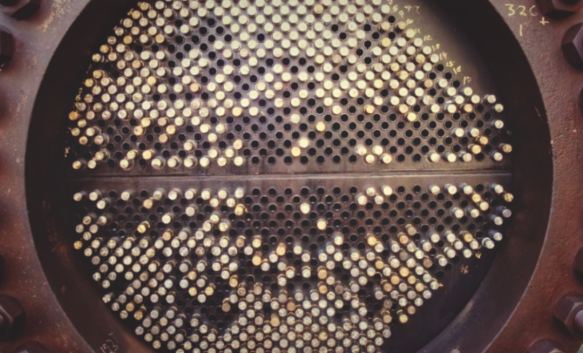

Heat exchanger tubes experience corrosion, erosion, and tube-end wear from aggressive process media and debris. Traditional responses include plugging tubes or replacing entire units.

Typical impact from extensive plugging

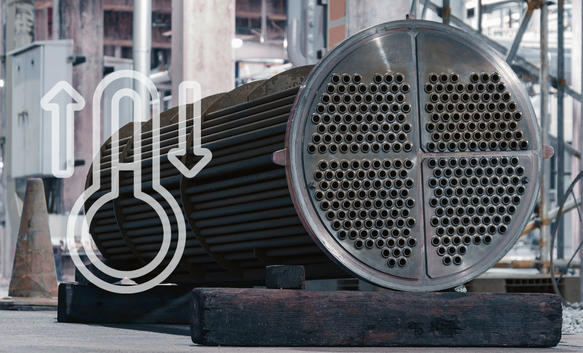

Full-length hydraulically expanded liners provide metal-to-metal contact barrier protection while maintaining heat transfer efficiency. Onsite installation minimizes downtime.

Restored tube functionality

Hydraulically expanded liners provide immediate corrosion protection while maintaining operational efficiency through proven metallurgy upgrades and expert installation.

Restore compromised tubes to full service capacity, avoiding volume losses from plugging strategies.

Protect parent tubes from further degradation through specialized alloy barriers designed for specific process conditions.

Avoid premature unit replacement through targeted tube rehabilitation that addresses root cause failures.

Maintain optimal performance through metal-to-metal contact installation that prevents insulating air gaps.

Complete installations within typical turnaround windows through efficient onsite processes and small crew requirements.

Access specialized alloys including 316SS, 825, C276, and duplex materials for enhanced corrosion resistance.

Select appropriate alloy based on process conditions and order properly sized annealed liners

Clean tube ID through grit blasting and measure parent tube dimensions for calibration

Install full-length liners into parent tubes with proper positioning

Expand liners using calibrated hydraulic pressure to achieve metal-to-metal contact

Cut liners to tubesheet specifications

Mechanically roll to expand ends as required

Proven solutions for extending heat exchanger life through expert metallurgy and installation techniques

Reach out to discuss your specific tube conditions and process requirements

Our technical team evaluates your application and recommends appropriate alloy specifications

Develop installation timeline and coordinate with your turnaround schedule

Deploy certified technicians for onsite liner installation and quality verification

01

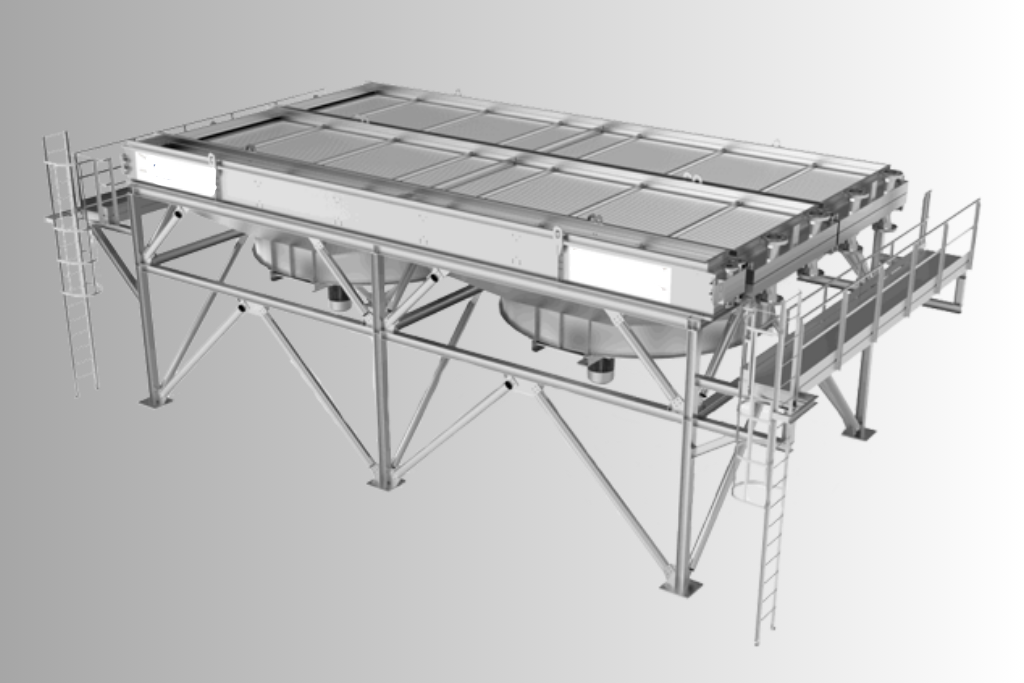

Heat exchangers, condensers, coolers, fin fan units, reboilers, and feedwater heaters experiencing corrosion, erosion, or tube-end degradation issues.

02

Typical installations complete within 6-day turnaround windows, depending on unit size and tube count. Our efficient process minimizes downtime requirements.

03

We provide liners in stainless steel (304/316), duplex, Inconel, CuNi, C276, 825, and other specialized metallurgies based on your specific process conditions.

04

Our hydraulic expansion process creates metal-to-metal contact between the liner and parent tube, preventing insulating air gaps that could reduce heat transfer performance.

05

Clients typically achieve substantial savings by avoiding unit replacement costs, with most projects delivering savings exceeding $500,000 compared to equipment replacement alternatives.

Please enter your name and email. We’ll be in touch soon.