Curran International has been setting the pace for industrial coating innovation since the early 1980s. What began with epoxy coating applied to heat exchanger tubes to protect cooling water systems from corrosion, quickly evolved as the demands of the refining and chemical industries shifted. The growing need to reduce fouling, minimize energy losses, and extend run times pushed Curran to develop coating technologies for services where coatings had never been used before. Relentless R&D pushed us beyond thick film epoxies to today’s ultra-thin, high-temperature resistant, low-surface-energy coatings that are revolultionizing heat transfer equipment in demanding process service conditions.

Fouling remains one of the most persistent and costly problems in our industry, responsible for billions in lost output, energy waste, and unplanned maintenance each year.

That challenge became the foundation of our Joint Development Agreement with Chevron, launched over 15 years ago to address fouling. The results are proven, field-tested solutions now applied to tens of thousands of exchangers worldwide. These coatings deliver longer run times, reduced cleaning intervals, and millions in recovered productivity for refiners and chemical operators across the globe.

Heat exchanger fouling/corrosion costs the process industry billions annually in lost efficiency and maintenance.

Surface Energy Increase

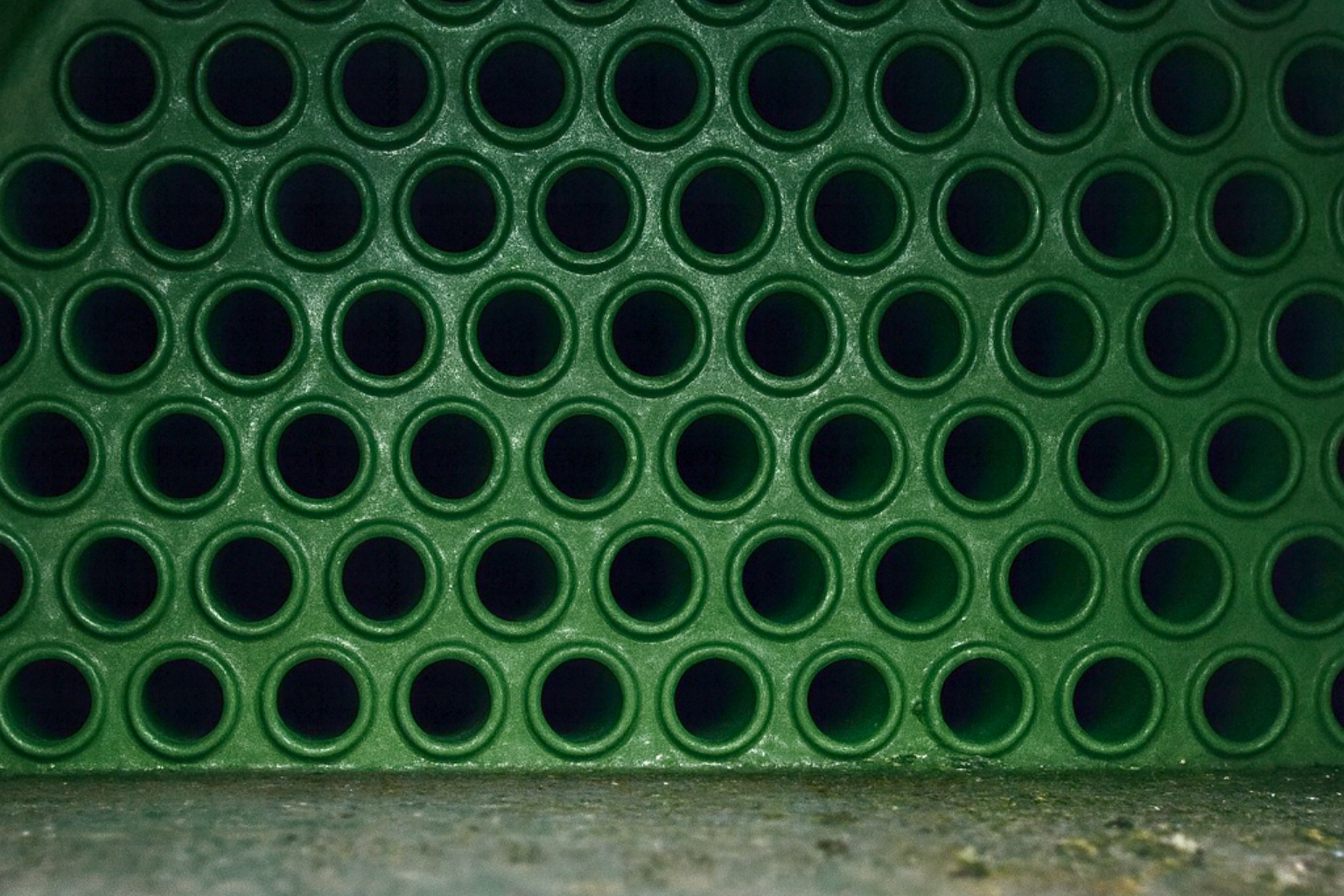

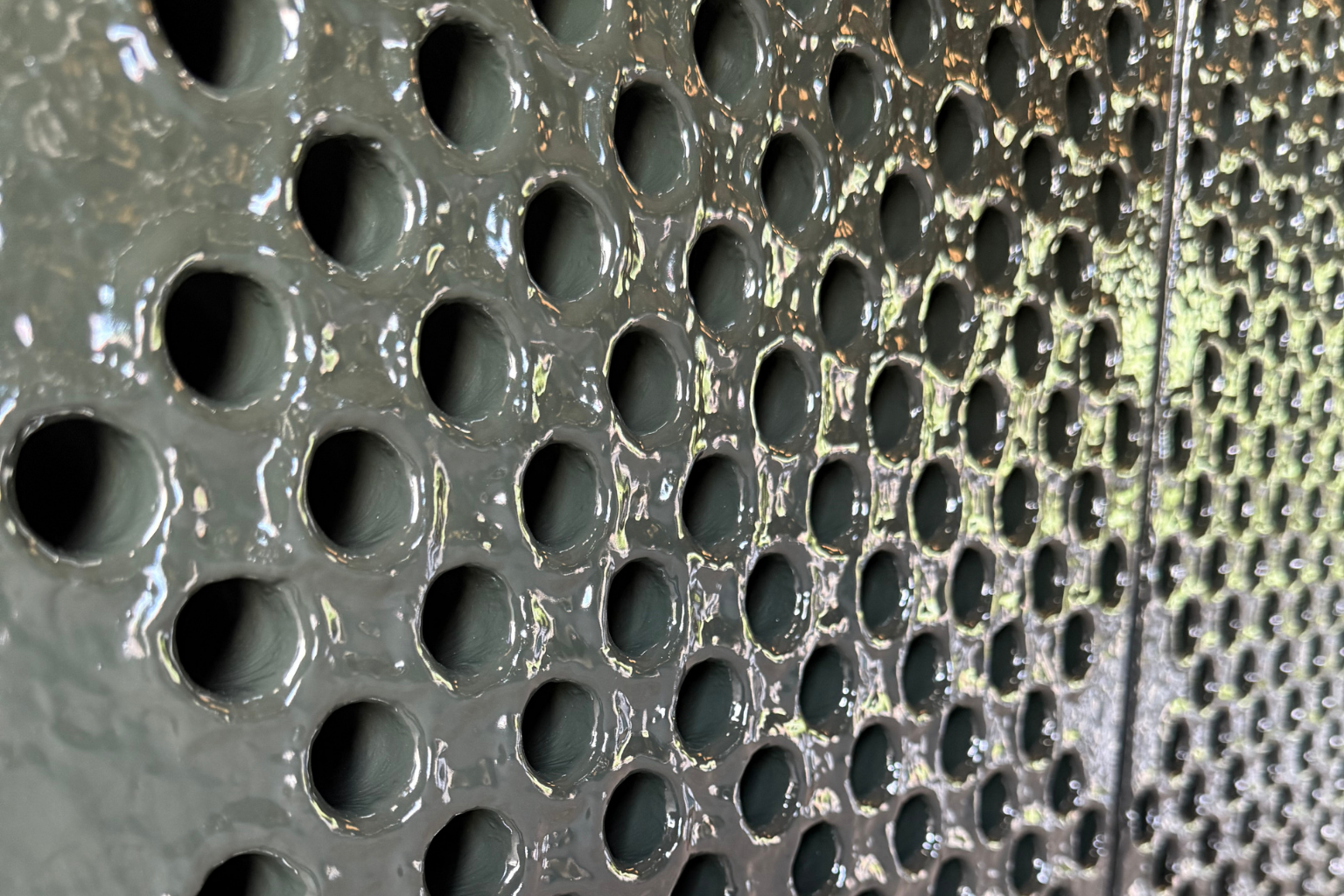

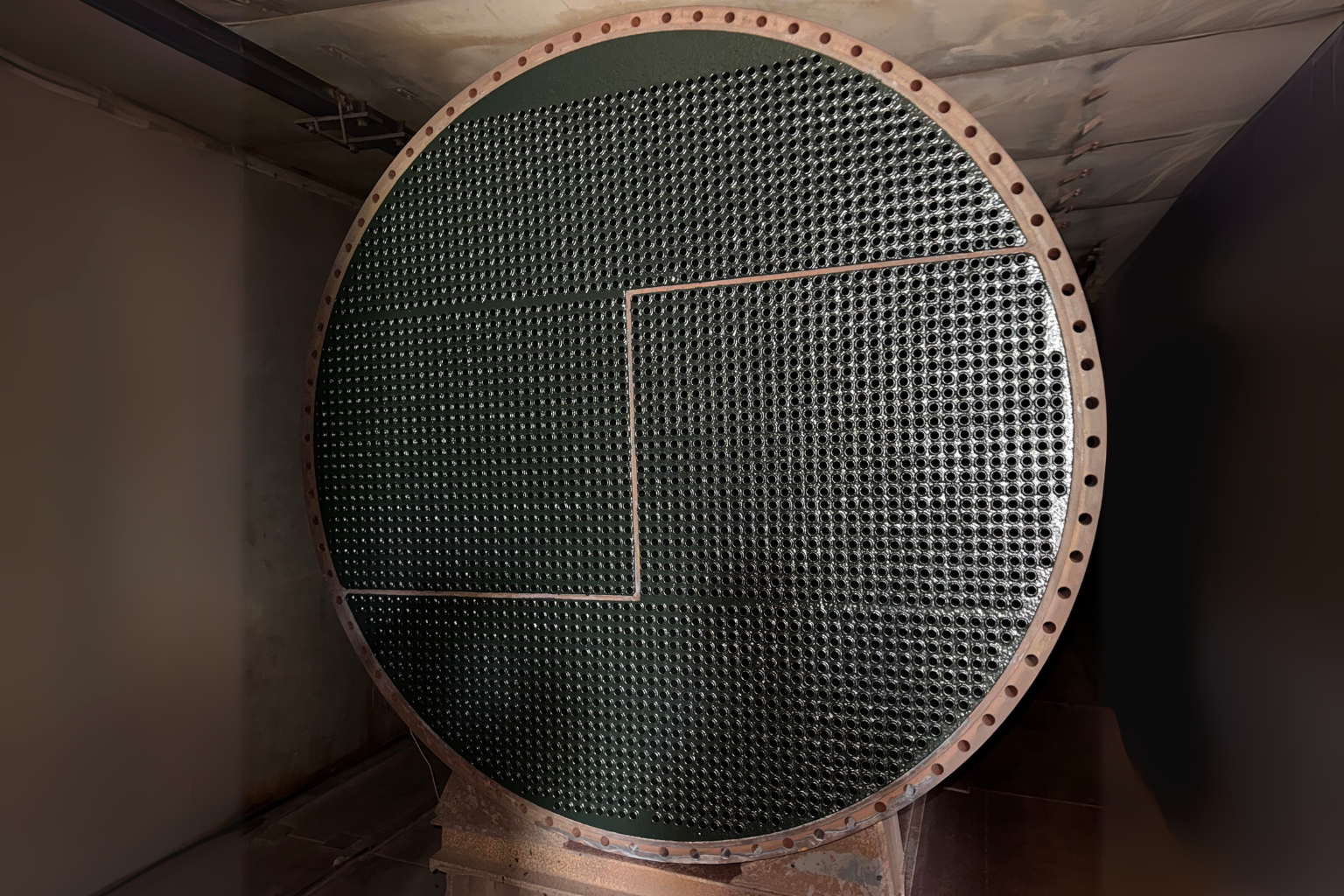

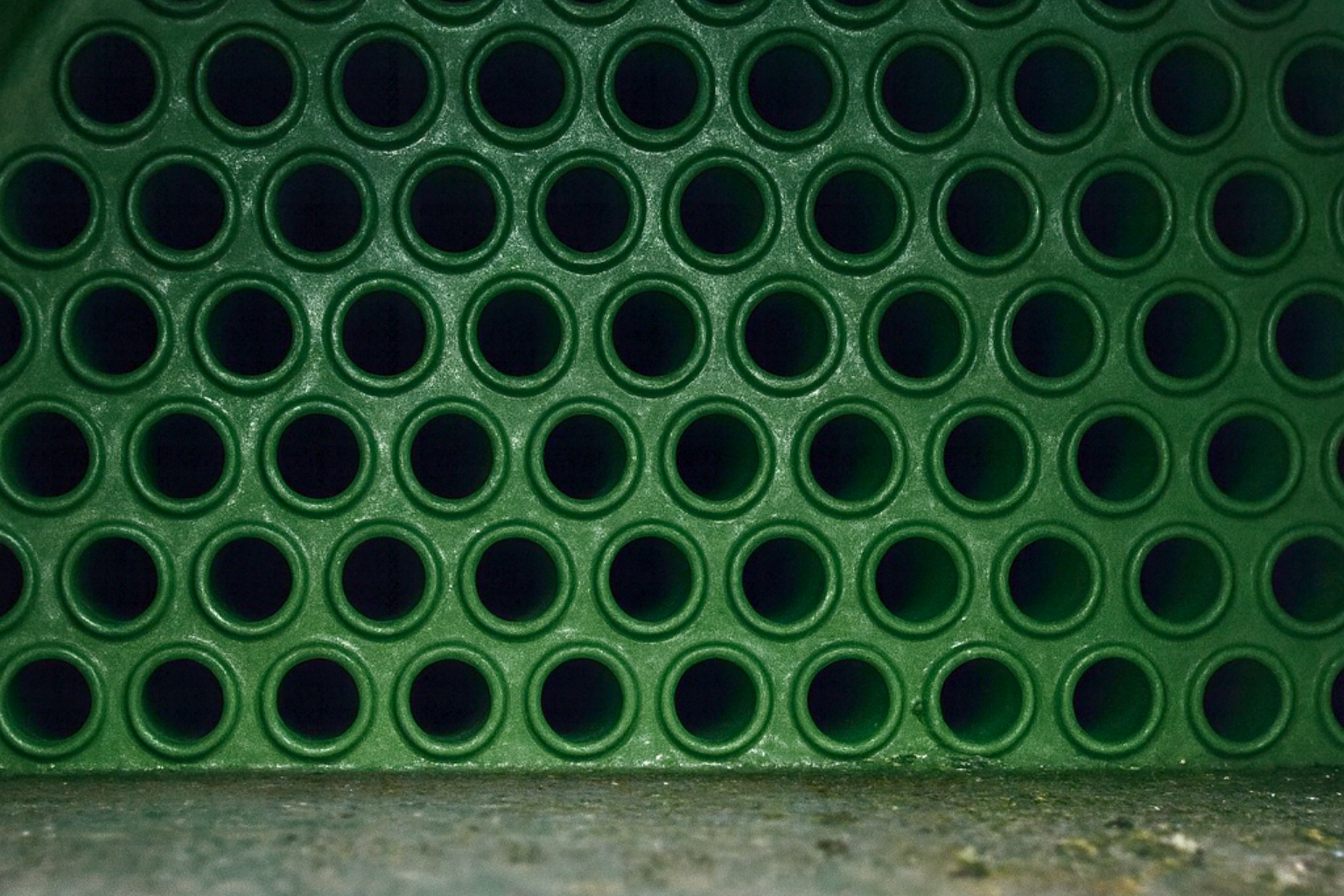

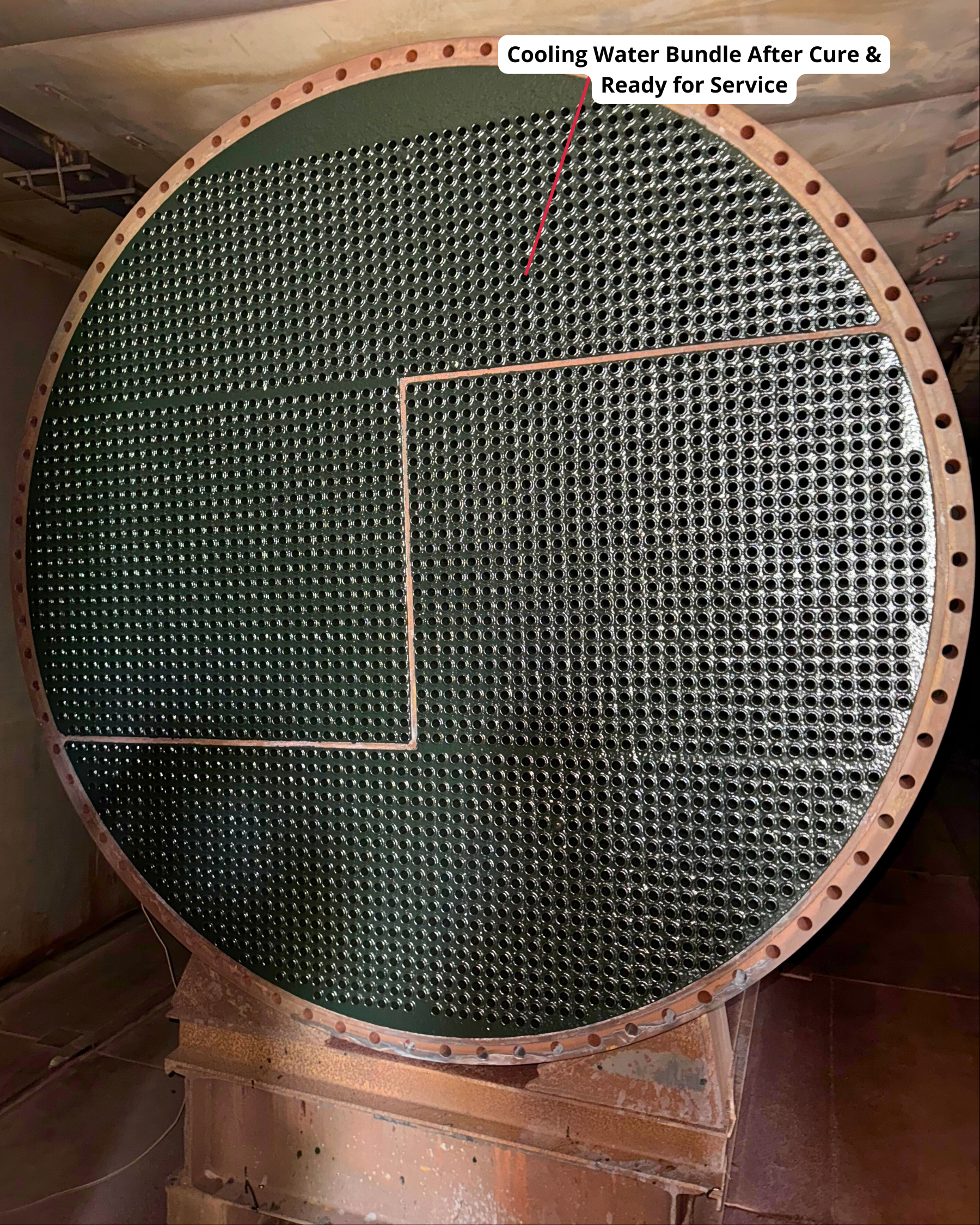

Curran 1000T epoxy, applied to tube IDs and tube sheets, forms a durable barrier that protects against corrosion and reduces foulant accumulation.

Field-proven solutions extending operation between cleanings

Cooling water solutions can significantly improve site reliability and efficiency by extending cleaning intervals from annual to multi-year cycles, some systems have run over 8 years without interruption.

They help prevent unplanned downtime by reducing fouling-related performance drops, while maintaining optimal heat transfer, flow rates, and pressure conditions.

The result is higher throughput, fewer shutdowns, and a lower total cost of ownership through reduced maintenance, cleaning, and replacement costs.

Extend cleaning intervals from annual cycles to multi-year operation, with documented cases achieving 8+ years continuous service

Provide predictable performance reducing emergency shutdowns from fouling spikes or under-deposit corrosion

Maintain design heat transfer coefficients longer by preventing insulating deposit buildup on tube surfaces

Enable higher flow rates and reactor temperatures – documented 950 m³/hour additional cooling capacity achieved

Maintain optimal pressure drops with documented 10 psi reductions in shell-side backpressure

Reduce repetitive cleaning costs, chemical waste disposal, and premature bundle replacement expenses

01

02

03

Click Here to Learn More.

04

Grit blasting to Near White/White Metal standards (SSPC- SP10/NACE No.2) with 1-3 mil anchor profile

High-pressure airless spray application (minimum 60:1 pump) building 8-14 mils dry film thickness

Ambient cure process (24-48 hours handling, 5 days full chemical cure) or accelerated heat cure

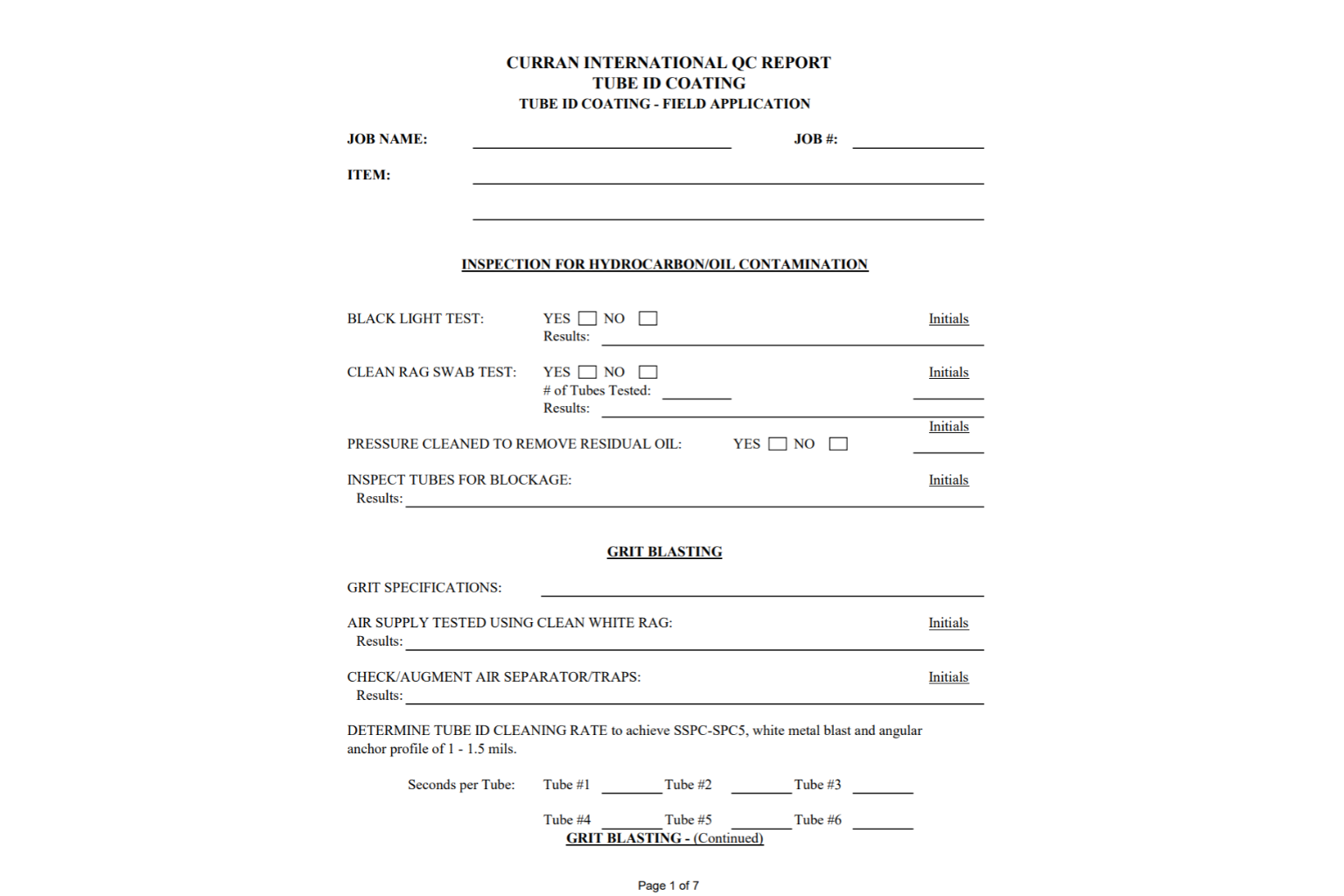

Includes holiday detection testing at 67.5 VDC, dry film thickness (DFT) measurements, and inspection by NACE-certified personnel.

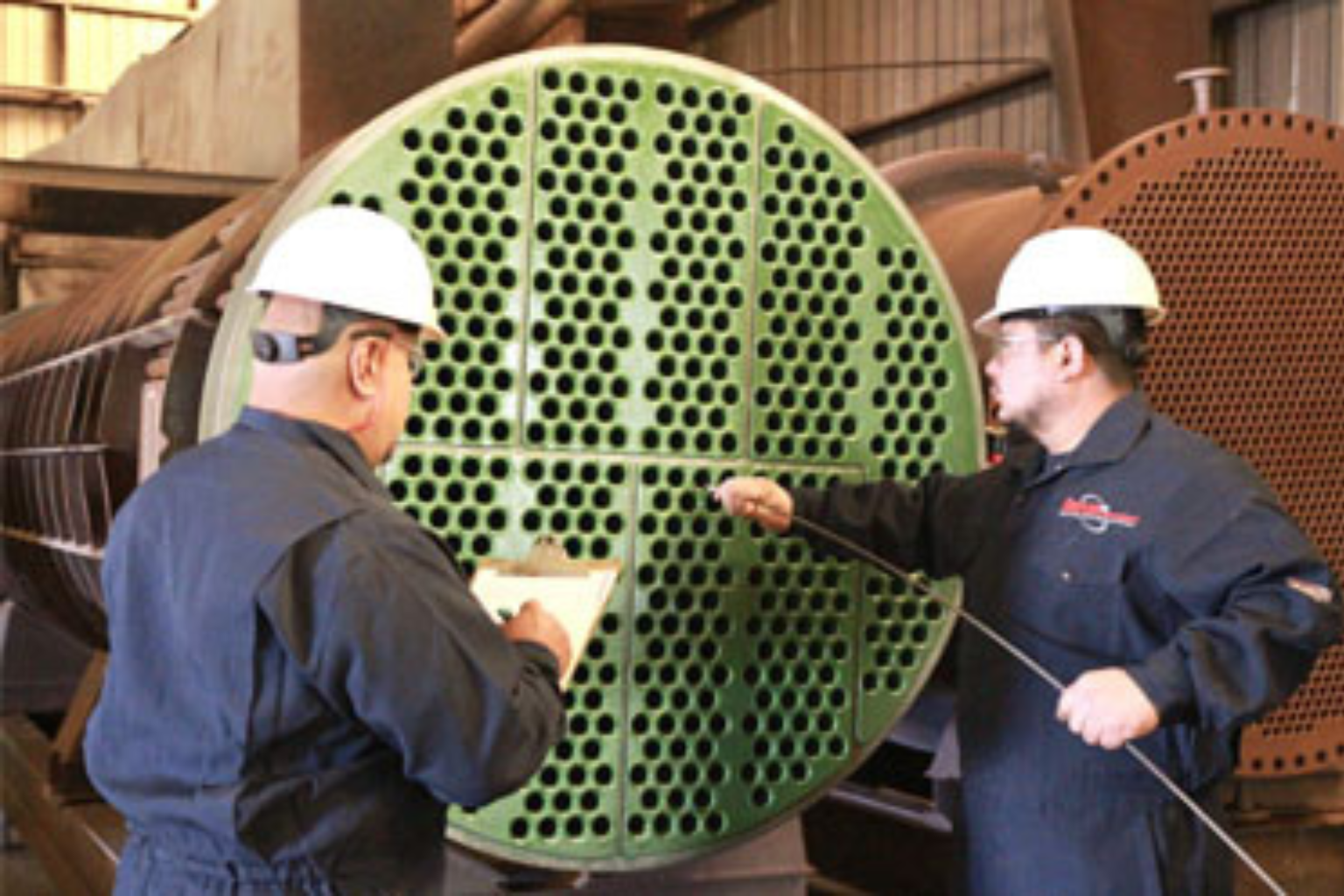

Complete service by experienced crews, available in Curran’s 20,000 sq. ft. facility or on-site during turnarounds.

Full quality documentation with inspection test plans (ITPs) and no special start-up needed—coated surfaces are ready for immediate service.

Proven solutions backed by 25+ years of field experience and over 100,000 successful installations

Evaluate your current fouling/corrosion challenges and operating conditions

Select optimal coating system and develop application specifications

Execute turnkey surface preparation and coating application

Provide ongoing technical support and performance monitoring

01

No - Curran's ultra-thin coatings (typically 1-3 mils) add minimal thermal resistance. The reduction in fouling buildup more than compensates for any film resistance, with exchangers maintaining better heat transfer over extended run lengths.

02

Field experience demonstrates multi-year to decade-plus performance. Documented cases include 15+ years service life in cooling water applications, with strong adhesion (3,000+ psi pull-off strength) and resistance to thermal cycling up to 400°F.

03

Curran 1000T handles continuous exposure up to 365°F (185°C) with steam-out excursions to 400°F. It resists various water chemistries from fresh to brackish/salt water and typical treatment chemicals. For more aggressive conditions, specialized formulations are available.

04

Yes - Curran provides both shop coating services and field application capabilities. Field crews can perform complete surface preparation and coating application on-site using portable equipment, with typical cure times of 1-2 days minimum.

05

Maintenance is simplified - avoid aggressive mechanical cleaning or acid treatments. Most fouling can be removed with low-pressure water rinse or soft brush. The coating can be locally repaired if mechanically damaged, and routine inspection methods (ECT, IRIS) remain effective.

Please enter your name and email. We’ll be in touch soon.