Reducing fouling. Increasing duty. Delivering measurable savings.

Crude preheat exchangers are critical to refinery throughput, energy efficiency, and operational reliability. When fouling and pressure drop are minimized, plants see higher production yield, lower energy use, and reduced CO₂ emissions.

Curran International’s Curramix 3500™ anti-foul coating has been engineered specifically to address these challenges — and the data proves it.

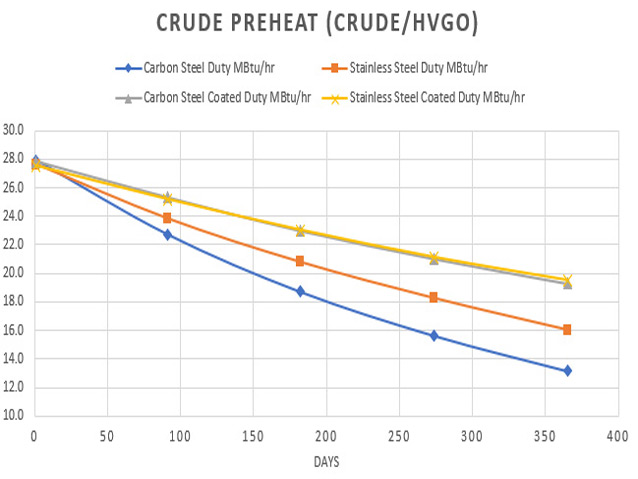

Study Compares Coated vs. Uncoated Exchanger

A performance study compared two mid-train TEMA AES crude preheat exchangers — one coated with Curramix 3500™, and one left uncoated. Both were modeled using Heat Transfer Research, Inc. (HTRI) software over one- and two-year intervals.

Key findings:

- Reduced backpressure and improved heat duty in coated exchangers.

- Significant CO₂ reduction through better thermal efficiency.

- $173,000 in combined maintenance and energy savings over a two-year run (based on cleaning the uncoated exchanger annually).

How It Works

The test exchanger was internally coated along the full-length tube IDs with a thin-film (25–35 microns) ceramic layer of Curramix 3500™. This advanced formulation reduced the substrate surface energy to 30 dynes/cm², improving release performance four-fold over uncoated carbon steel.

The result? Slower fouling, sustained heat transfer rates, and extended run times between cleanings.

In-Field Validation

Real-world refinery trials confirm the lab data:

- More than 36 months of effective service in operating units.

- Run times up to three times longer than uncoated exchangers in identical conditions.

Coating Solutions for the Harshest Services

Curran offers a complete portfolio of heat exchanger coatings for crude and hydrocarbon processing, including:

- Organic hybrid, ceramic, and Teflon™ materials

- Application for services up to 750°F

- Thicknesses as low as 5–15 microns for minimal impact on heat transfer

- Proven performance in vacuum bottoms, FCC slurry, produced water, desalting, and other high-fouling environments.

These materials are engineered and applied worldwide to help refineries:

- Maintain longer operating cycles

- Reduce energy consumption

- Lower maintenance costs

- Improve environmental performance

📩 Contact: Edward Curran

📧 ecurran@curranintl.com | ☎ (281) 339-9993