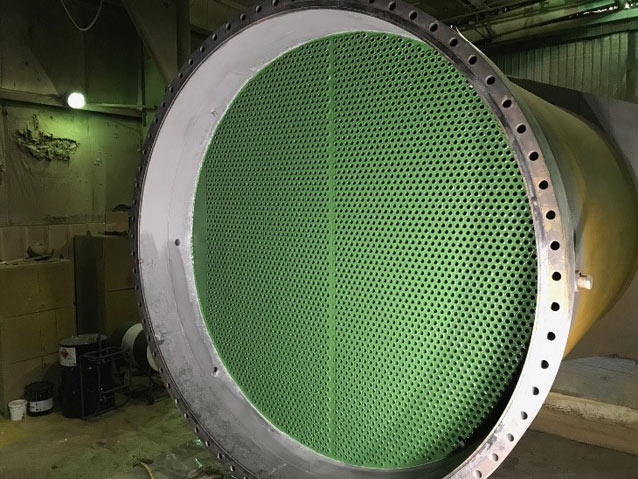

Curran International continues to expand its portfolio of coating materials and applications designed to prevent heat exchanger fouling. Our advanced coatings are engineered for challenging services, including crude pre-heat, vacuum bottoms, FCC slurry, and produced water (oil/water) separators. Both organic hybrid and inorganic coatings provide exceptional foul-release performance while maintaining thermal and hydraulic efficiency.

Ultra-Thin Coatings, Maximum Performance

Some Curran coatings are fully functional at 5–15 microns total thickness, modifying substrate interactions by:

- Reducing surface tension to <30 dynes/cm²

- Minimizing surface roughness to ~0.5 microns

These ultra-thin coatings improve foul release, enhance hydrophobic and oleophobic performance, and sustain heat transfer and flow.

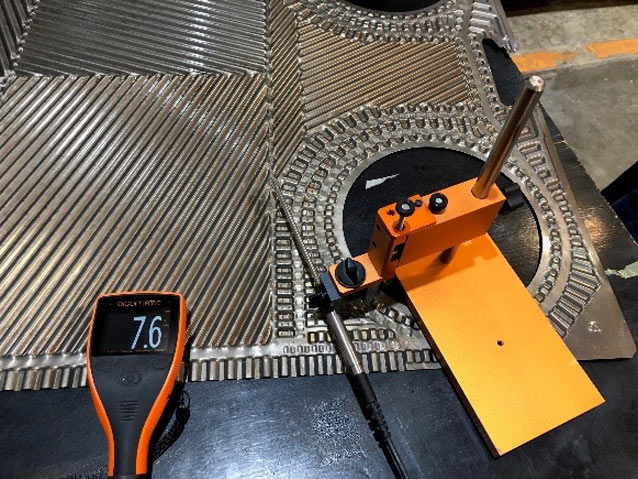

Example: For Plate & Frame Exchangers, a positioning jig is used to ensure precise application, with measured film thickness of 7.6 microns. Other coatings may be applied at 125–300 microns for heavier-duty services.

Proven Field Performance

Curran coatings improve release properties and minimize fouling nucleation sites. Field trials of 15–60 months demonstrate superior results compared to uncoated exchangers in the same service.

These Curran Coatings reduce surface tension, increase repellency, and promote sheer to contribute to sustained thermal and hydraulic performance.

Notable highlights:

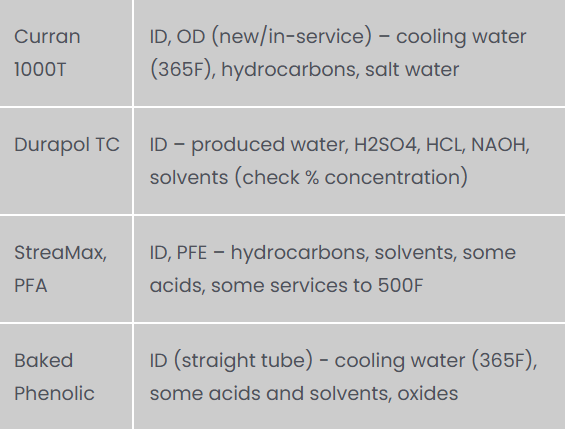

- Curran 1000T and Durapol TC can be field-applied and cured, including for U-tube exchangers.

- Application facilities are available in Houston, Edmonton, Rotterdam, and Singapore.

New Materials Help Solve Old Problems

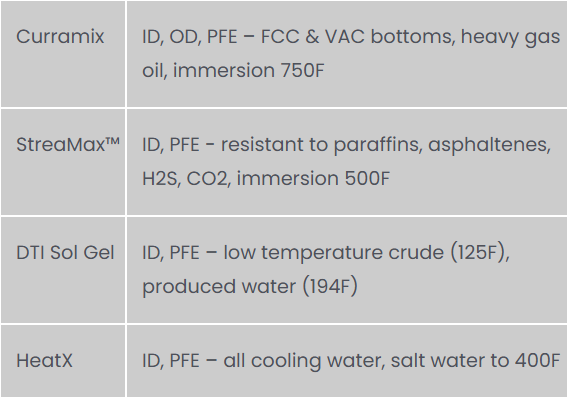

New materials contribute to a growing portfolio of Curran protective tube coatings, facilitating exchanger applications for wider range of refinery and petrochemical services.

These Curran Coating, which are applied at 125 to 300 microns total thickness, offer hydrophobic and oleophobic release, and are suitable for all cooling water services.

Continuous Product Development

Curran continues evaluating new anti-foul coatings for high-temperature coking and furnace tube scaling. Early field trials are showing promising results in extreme refinery and petrochemical services.

To Learn More

Contact Edward Curran at (281) 339-9993 or ecurran@curranintl.com for details on Curran’s heat exchanger anti-foul coatings and our full portfolio of protective coatings.